3 Different Types of PTO Yokes

Tags : new-holland-landing | pto | yoke |

3 Different Types of PTO Yokes

Neil from Messick's here to talk to you a little bit today about PTO shafts, the shaft that takes the power from your tractor and transmits it back to your implement. There are actually several types of PTO shafts down here. The end that hooks onto your tractor can be engineered in a couple of different ways, and there's some differences when it comes to service and maintenance, and also the angle that that shaft can run at in relation to your implement. So today, we're going to go and talk about PTO shafts.

Yolk Joints

What I have here is the most common type of PTO shaft. This is called a yolk joint. A yolk joint is going to have two U-shaped yolks that go 90 degrees to one another with a cross that goes across the middle that supports them. Now those are going to move very freely when they're in line with one another, and they can rotate around their respective axes. But when they start to be off center from one another, you can get some chattering motion that you're going to notice. And you'll notice that in your implements, when you take your three-point hitch, say the whole way down, or you're making a headland turn, and your tractor is running at a hard angle from your implement, you'll start to hear a chatter from your yoke joints. They'll start jumping around a little bit. That noise that you're hearing when it gets to those more extreme angles is that shaft fighting as it goes around, and over time, it'll start to wear out the cross piece that sits in the middle of that joint. Now, these parts are easily replaceable and generally readily available. So if you do wear one of those out, it becomes a service point. Right? Something that you step into and replace that little part if you happen to wear it out over time. These shafts are extremely popular. They're extremely inexpensive. And they're found on most equipment.

Constant Velocity PTO

However, there's another alternative called a constant velocity PTO shaft. Now you notice that the shaft on this PTO is much larger than the yolk joint PTO that we were just looking at. That's because this is a CV joint PTO. Now a CV joint is going to run at much harder angles than what a yolk joint PTO is able to, and it will do it without chattering. That's because mechanically, this is using a series of plates and ball bearings in order to transfer power through this joint rather than those yolk joints.

Now it's going to be at some expense. It is a more expensive shaft, significantly more expensive when we get into higher horsepower models, and it's going to be physically a little bit larger. You see how big this end is right now. That can make it a little bit more difficult to fit onto the back of your tractor. So you're going to want to keep an eye out for that. Now, while this is great in this baler application, right? We go to the end of our headland. We make our tight turnaround back into our next windrow. We need to be able to keep this thing spinning the entire time so that our baler stays running. It is becoming less and less common on a lot of equipment, and I'll show the alternative.

Swiveling Gearbox

This is a New Holland Discbine right here that generally you would find with one of these CV joints on it. Right? You're doing tight headland turns as you're going back and forth. But you see here, this has a regular yolk joint on the end of it. That's because this has a swiveling gearbox. These swivel gearboxes are becoming more popular on equipment all the time because it allows you to turn at almost any angle, even angles far beyond what a CV joint is going to tolerate, and keep these shafts completely in the line at all times. Some of these other mechanical solutions are becoming more and more common and are part of the reason why I struggled so much out here today, walking around, trying to find a CV joint.

I hope that helps you understand the differences between these PTO shafts a little bit. It's important to be able to pick up on this kind of stuff if you're shopping for a piece of equipment because the differences between these two shafts can literally have hundreds, if not thousands of dollars of impact in the cost of the implement that you might be shopping for. A really deluxe implement that's coming through with that CV PTO shaft on it would have a lot more value tied up in those dollars than, say, a less expensive one using yolk joints, and it may or may not be right for the kind of application that you have.

More Articles

Field Sprayer Maintenance Tips

Hi, David from Messick's here with today's three-minute Thursday. Today we're going to talk about some helpful hints and tricks that'll help you with your sprayers out in the field.

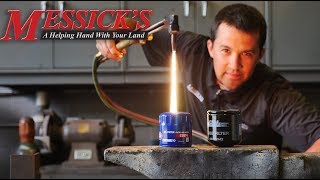

CUTTING MORE OIL FILTERS - Case/New Holland VS. STP

Today, we're going to go through our third filter cutting that we've done using a new Holland oil filter. This would be the most common oil filter in the new Holland system. Then we're intentionally choosing a really inexpensive filter to compare it to this time

One of the things that I feel is missing a little bit from the tractor buying resources that are out there is a real way to go through and distinguish between these premium and basic models. There can be some very significant differences between tractors. And I feel like when you go through and you watch the YouTube video of somebody who's bought a piece of equipment, or you go through manufacturer literature, that's always positive about a machine, you start to lose some of the finer points of ergonomically what a machine is like to operate or what the experience is like in the driver's seat. It's one of those things that you can really only pick up on when you have opportunities like I do to be around this stuff all the time. There are things on this machine that are frankly not the best. It's not the best that New Holland has to offer, that many companies do.