New Holland Round Baler Buyer's Guide

Tags : new-holland-landing | round-baler |Understanding New Holland Round Balers: What Makes One Model Different from Another?

Quick Summary

Not all round balers are created equal. New Holland offers a wide range of round baler models that may look similar at first glance, but vary significantly in size, capacity, features, and price. From entry-level utility balers to heavy-duty commercial machines, this guide breaks down the key differences to help you determine which New Holland round baler is the right fit for your operation.

Why Round Baler Differences Matter

It’s easy to assume that one round baler works much like another, but differences in design, construction, and features can dramatically impact productivity, bale quality, and long-term ownership costs. New Holland’s round baler lineup is engineered to meet the needs of very different customers, from small acreage operators to high-volume commercial producers.

What All New Holland Round Balers Have in Common

Across the entire lineup, New Holland balers share a commitment to build quality, reliability, and long-term parts support. Many of these machines are designed, engineered, and manufactured near New Holland, Pennsylvania, with local suppliers supporting castings, machining, and assembly.

This localized manufacturing approach proved especially valuable during supply chain disruptions, helping New Holland maintain availability and support when other products struggled. For many customers, this reliability and domestic production are key reasons for choosing New Holland.

RB450 Utility Plus: An Entry-Level Starting Point

The RB450 Utility Plus is the most economical round baler in New Holland’s lineup. While it produces the same 4x5 bale size as larger models, the machine itself is physically smaller and lighter. It features narrower pickups, lighter hitches, smaller PTO components, and fewer heavy-duty materials.

This baler is ideal for operators putting up a few hundred bales per year or those baling as a secondary or hobby operation. Importantly, this model is now built domestically in Pennsylvania, offering the same parts availability and support as higher-end models.

RB450 Standard and Silage Special Models

Moving up the lineup, the standard RB450 features a much larger and heavier frame. This added structure allows for a wide range of configurations, including dry hay and silage special versions.

Silage Special models are particularly popular in regions where wet or heavy forage is common. These balers include endless belts, belt scrapers to remove wet debris, and heavier pickups to handle tougher conditions without compromising performance.

RB450 Crop Cutter: Higher Density and Feed Efficiency

The RB450 Crop Cutter adds a rotor and knife system behind the pickup. This system cuts hay into shorter lengths before it enters the bale chamber, producing tighter, denser bales.

Crop Cutter balers are especially valuable for operations using feed mixers, as shorter material mixes more easily and evenly. While this system increases cost and horsepower requirements, it delivers meaningful benefits in feed quality and handling.

RB450 Bale Slice: A Unique New Holland Option

For operators who want some benefits of chopped material without the complexity of a full cutter system, the Bale Slice option offers a middle ground. Instead of cutting hay completely, knives score the material as it passes over the pickup.

This system improves bale breakup and feed mixing while keeping costs and maintenance lower. Bale Slice is a New Holland-exclusive feature not commonly found in competing balers.

Pro-Belt 450: Built for High-Volume Production

The Pro-Belt 450 represents the heavy-duty end of the 4x5 baler spectrum. Designed for extreme duty cycles, it features massive chains, bearings, and structural components built to handle thousands of bales season after season.

While the upfront cost is significantly higher, this baler delivers unmatched durability, uptime, and throughput for large operations where productivity is critical.

RB560: Stepping Up to 5x6 Bale Size

The RB560 produces larger 5x6 bales and offers many of the same feature options as the RB450 series. However, bale size and weight are major considerations. Larger bales require heavier tractors, loaders, and handling equipment.

In many operations, 5x6 bales are best suited for on-farm use rather than resale, as transportation and handling become more challenging.

Choosing the Right New Holland Round Baler

Selecting the right baler comes down to matching machine capability with your operation’s scale, forage type, and handling equipment. While it’s tempting to focus on price alone, understanding how features, duty cycle, and bale size affect long-term performance can prevent costly mistakes.

Working with knowledgeable sales specialists ensures you’re choosing a baler that fits your farm today and supports your needs in the future.

Frequently Asked Questions

What is the difference between the RB450 Utility Plus and Pro-Belt 450?

The Utility Plus is designed for low-volume, budget-conscious operators, while the Pro-Belt 450 is built for high-output commercial use with heavier components and significantly greater durability.

Is a silage special baler worth it?

If you regularly bale wet or heavy forage, a silage special baler offers better belt cleaning, durability, and reliability in challenging conditions.

What are the benefits of a crop cutter baler?

Crop cutter balers produce denser bales and improve feed mixing efficiency by shortening forage length, making them ideal for livestock operations using feed mixers.

Why are 4x5 bales more common than 5x6 bales?

4x5 bales are easier to transport, stack, and handle with common farm equipment, making them more versatile for many operations.

How do I choose the right New Holland round baler?

Consider your annual bale volume, forage type, handling equipment, and long-term goals. Consulting with an experienced equipment specialist can help ensure the best match.

450 Utility Plus

4 X 5, Net Only, 1.5M | 4 Bar Pick-Up, Manual Lift Pick-Up, Pick-Up Wheels, 11L-14 x 6 PR Rib Tires, Bale Ramp, MRT Laced Belts, 540 PTO, Clevis Hitch

450 RC

4 X 5, Rotor Cut, Silage Special, Net Wrap, Bale Ramp, 2.07M Rotary SuperFeed HD Pick-Up, Premium Endless Belts

450 SN

4 X 5, Silage Special, Net Wrap, Bale Ramp, 1.8M Active Sweep HD Pick-Up, Premium Endless Belts

450 SL

4 X 5, Bale Slice, Silage Special, Net Wrap, Bale Ramp, 1.8M Active Sweep HD Pick-Up, Premium Endless Belts

Roll-Belt Series

OUTSTANDING CAPACITY, DENSITY & INNOVATION

More Articles

Field Sprayer Maintenance Tips

Hi, David from Messick's here with today's three-minute Thursday. Today we're going to talk about some helpful hints and tricks that'll help you with your sprayers out in the field.

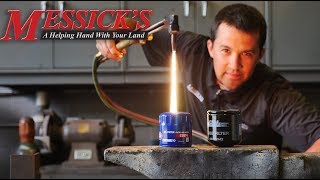

CUTTING MORE OIL FILTERS - Case/New Holland VS. STP

Today, we're going to go through our third filter cutting that we've done using a new Holland oil filter. This would be the most common oil filter in the new Holland system. Then we're intentionally choosing a really inexpensive filter to compare it to this time

3 Different Types of PTO Yokes

There are actually several types of PTO shafts down here. The end that hooks onto your tractor can be engineered in a couple of different ways, and there's some differences when it comes to service and maintenance, and also the angle that that shaft can run at in relation to your implement. So today, we're going to go and talk about PTO shafts. What I have here is the most common type of PTO shaft. This is called a yolk joint. A yolk joint is going to have two U-shaped yolks that go 90 degrees to one another with a cross that goes across the middle that supports them. Now those are going to move very freely when they're in line with one another, and they can rotate around their respective axes. But when they start to be off center from one another, you can get some chattering motion that you're going to notice. And you'll notice that in your implements, when you take your three-point hitch, say the whole way down, or you're making a headland turn, and your tractor is running at a hard angle from your implement, you'll start to hear a chatter from your yoke joints. They'll start jumping around a little bit. That noise that you're hearing when it gets to those more extreme angles is that shaft fighting as it goes around, and over time, it'll start to wear out the cross piece that sits in the middle of that joint.