Proven. Preferred. Powerful. What makes CNH disc blades different?

Tags : new-holland-landing |1. Iron ore, limestone and coal to restrict contaminants. Contaminants weaken the end product.

2. Oxygen furnace is used, not Electric Arc furnace. Electric Arc furnaces permit contaminants.

3. Earth Metal microscopic structure encapsulates sulfur, eliminating layers of sulfur, which are fracture points.

4. Material-handling robots assure quality control and consistency to form and cool simultaneously in seconds, every time.

5. Coated with high-gloss enamel, which is baked to a hard finish that provides rust protection.

6. An inline oven draws each blade individually, which relieves internal stresses

and improves ductility and quality.

7. Brinell or Rockwell tests measure hardness to ensure resistance to wear.

8. Tested for elasticity under load by applying pressure to the blade—the

propensity of the blade to return to its original shape afterward is a measure

of its ability to resist impact.

More Articles

Field Sprayer Maintenance Tips

Hi, David from Messick's here with today's three-minute Thursday. Today we're going to talk about some helpful hints and tricks that'll help you with your sprayers out in the field.

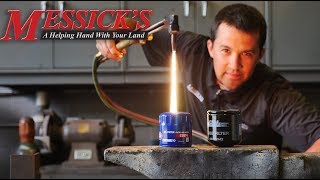

CUTTING MORE OIL FILTERS - Case/New Holland VS. STP

Today, we're going to go through our third filter cutting that we've done using a new Holland oil filter. This would be the most common oil filter in the new Holland system. Then we're intentionally choosing a really inexpensive filter to compare it to this time

3 Different Types of PTO Yokes

There are actually several types of PTO shafts down here. The end that hooks onto your tractor can be engineered in a couple of different ways, and there's some differences when it comes to service and maintenance, and also the angle that that shaft can run at in relation to your implement. So today, we're going to go and talk about PTO shafts. What I have here is the most common type of PTO shaft. This is called a yolk joint. A yolk joint is going to have two U-shaped yolks that go 90 degrees to one another with a cross that goes across the middle that supports them. Now those are going to move very freely when they're in line with one another, and they can rotate around their respective axes. But when they start to be off center from one another, you can get some chattering motion that you're going to notice. And you'll notice that in your implements, when you take your three-point hitch, say the whole way down, or you're making a headland turn, and your tractor is running at a hard angle from your implement, you'll start to hear a chatter from your yoke joints. They'll start jumping around a little bit. That noise that you're hearing when it gets to those more extreme angles is that shaft fighting as it goes around, and over time, it'll start to wear out the cross piece that sits in the middle of that joint.