The LARGEST Track Loader Ever | New Holland C362

Tags : construction-equipment | new-holland-c-series-trackloader |

The LARGEST Track Loader Ever | New Holland C362

This is a brand new pre-production machine New Holland brought in here for our open house to be able to show off a little bit. Interestingly, this one's headed on the road right now, down to the Louisville Construction Show. So before they take this thing out of here, we're going to do a quick walk around here with you a little bit, and show you a little bit about what makes this thing special. If you come around the side here with me, you'll notice that this isn't just any old track loader, the size of this thing is absolutely enormous. This is now the largest track loader anywhere in the industry. It has a weight of over 16,000 pounds. It's nearly as heavy as some of Cat's dozers, but even then it has more horsepower. Those small dozers usually start in the 80 horsepower range, this thing comes in at 115.

It's got a rated operating capacity of 6,200 pounds. Literally, it can lift up and carry around some of the smaller track loaders that are out here in this class. So we're going to walk you around and show you a little bit about this impressive machine. I'm hoping in the video, you can understand this sheer scale in size of what this thing is. A lot of times when you look at a track loader, they appear to be mostly cab with an engine behind them. And this is almost the inverse, if you say, take the scale on the bulk of the engine compartment versus the cab capsule that's up here on the front. Now the cab itself is just like the rest of the other New Holland 300 Series machines. When you drop in there, the capsule itself's going to feel the same, the controls, everything, the screen up there with the backup camera and all that. Pretty much the same thing as what you would find in the other videos that we have done about this series, so we're not going to focus on those things, but look more at what makes this machine unique.

Super Boom Design

This is New Holland's super boom design, well known within the industry. Where most machines are vertical lifts that can go straight up, the super boom design actually goes straight up, but once it gets to the top of its path, it starts to come forward a little bit, and that helps it reach forward over the top of something, say to load a truck, or stack a bale where you're trying to place your load up here. That's different than radial lift machines, radial lifts that come up in an arc, start to go backward at the top of their lift arc, making this a much nicer design. The hinge pin height on this is a full 12 feet, right down here to the bottom of this pin when the thing is at full extension. So definitely helping you get up over the top of those larger still trucks.

Weight Distribution

The whole frame length is 11 feet long, from tip to tail, 11 feet. Now, in order to be able to have that much weight, that 6,200 pounds 12 feet up in the air, going forward a little bit, having a machine that's 11 feet long, you're going to notice a significant amount of counterweighting here on the back of the machine. Now, these counterweights are standard equipment on this, this is not an add-on weight package like you sometimes will find on machines like this. These huge counterweights are on the left and the right side, but also more counterweights are still tucked under the belly of the machine on the back. I think that's important, the location of all of that weight so far back behind the machine, because it is truly counter-weighting then, the capacity that you have on the unit out front.

How does it compare to a dozer?

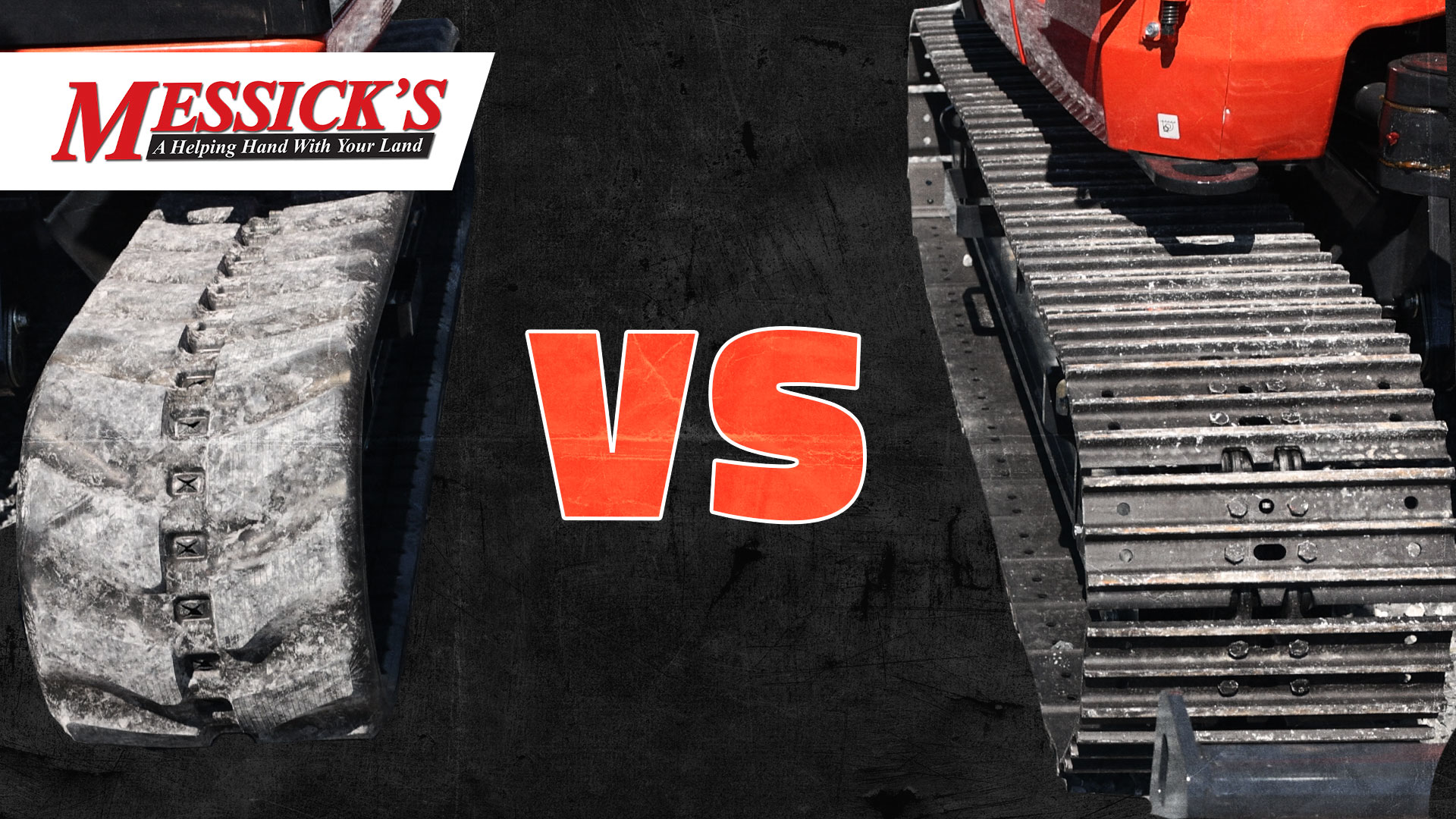

My dozer references were kind of intentional here at the beginning. There's construction in this thing that really kind of borrows from dozers. If you look at the way the track frame is pinned back into the machine, most of the time the track frames that you'll see on compact track loaders simply come out from the side of the machine in one place. However, this one has tie-ins up here in other areas to really get it tied rigidly back into the frame of the tractor. There are also these pivoting bars right here that go across the bottom of the machine in order to help keep that track frame straight. The size of the motors up here is absolutely enormous. There are six boggy rollers down here across the bottom and then dual flange rollers and the front and the back to really help keep that track on and planted. Now we generally are going to always order the rubber-tracked version of this, this is what our customers tend to demand around here for the kind of work that we usually see these machines doing. But if you're putting one in say, a scrapyard application, or were literally using it like a dozer with a blade on the front, as you could do, steel track variants of this are going to be available.

Hydraulic System

Now you probably can guess with this much power, you've got a hydraulic system to go along with it. The low-flow couplers are over here on your left-hand side. You're going to want to use those for implements that don't need huge amounts of hydraulic flow. However, if you need it, your high flow couplers are over here on the right. Now you take a look at the size of these couplers and the size of the long lines, they are enormous. This thing cranks out 41 gallons a minute of high flow but also has a high-pressure option as well. That will allow you to go in and turn up the pressure of the hydraulic lines to 4,100 pounds. Now you're going to want to have supporting implements that know they can handle that amount of pressure. But not only is this machine producing that impressive flow, but it can also do it at a higher than normal hydraulic pressure.

Engine Compartment

We're going flip over the engine compartment here in the back, and I can't get over the scale of this. Usually, the top of the engine compartment on most machines on me is down about here. Flip open the top lid here, pull this lever, swing out the back, you'll find 114 horsepower turbocharged engine. Now, as far as serviceability goes, most of your daily checks and filters are right here in the back of the machine. You've got a large air filter up at the top, your hydraulic oil and def fill right here at the rear, filters for serviceability down here in the bottom, radiator overflows in the back, your daily checks are all here. Now you could guess, this has got a deep engine compartment to it, so in terms of deep serviceability, might take a little bit of an effort to really get down in here if you to. But most of your daily checks, the things that we're going to really encourage you to keep an eye on to make sure this machine operates well for you long term, are right here at the back of the machine. Uniquely in a skid steer like this, this has an option for a hydraulic reversing fan. Now hydraulic reversing fans in dusty environments are going to turn around the fan on the radiator and blow the air out to get whatever chaff or anything that might be collecting on the machine off in order to keep it cool.

Locked Battery Compartment

Another interesting feature here that I thought was thoughtful and unique is this little door here in the side. You could turn this, open it up, and inside of here is your battery to be able to pull it out the side if you need to change it. A jump port on here, if you're jumping this or another machine, and a switch right here for battery disable. If you're going to say, leave this thing on a job site, you can disable the electronics and then lock that door shut. This plate is pretty substantial. Nobody's going to crowbar their way into that.

More than Just a Bigger Machine

This isn't just taking a regular track loader and scaling it up by 25%, they actually took some care to go through and find unique things like this. It excites me to have something like this in our portfolio that is simply bigger than what anybody else has. We love these unique products where we can go out and find the right customer for something like this, something that nobody else really has to offer. We've priced this machine a lot since it's been here throughout our open house. We had a lot of interest from a lot of the people that you would expect, contractors, builders, that kind of thing, but also, farmers and stuff. People that might be working on manure pits, site pads, that kind of stuff, places where you can never have quite enough machine. You're able to go out and do some of that dozer-type work, but still be able to throw a bucket on and load that dirt afterward. So it can become a really versatile piece of equipment for you.

The list price on this thing is an absolutely eye-watering $137,000 (at the time of filming). It is a big chunk of change. However, we've had some really aggressive pre-sale discounts on this that bring it down to a point that you can kind of see, it's justifiable in the price of where modern equipment is selling right now if you look at say a 100 horsepower track loader, the incremental cost to go something like this is not terribly unreasonable. So if you're shopping for one of these things, we'd be glad to show one off to you. I would love nothing more than to go out and put this into a pile of dirt and run it around today, but I'm not allowed to since it's headed off to another's show.

More Articles

The durability of steel tracks is appealing but comes at the cost of damage to the surface it is driving over. These 8 differences will help you decide if you should get steel or rubber tracks on your next machine.