Baler Twine, Net Wrap, and Silage Wrap Explained: What You Need to Know

Quick Summary

Baler twine, net wrap, and silage wrap may seem like simple consumables, but the choices you make can directly impact bale integrity, efficiency, and overall profitability. This guide explains the differences between sisal and poly twine, how knot strength and length affect performance, why country of origin matters, and what separates premium net wrap and plastic wrap from budget options.

Why Baler Twine Still Matters

Baler twine is one of those products many operators assume are all the same, until something goes wrong. Broken knots, inconsistent length, or bales coming apart in the field can quickly erase any savings from cheaper twine. With the volume of twine used every year, even small differences in quality and consistency can have a meaningful impact on labor, cleanup time, and lost product.

The Two Main Types of Baler Twine

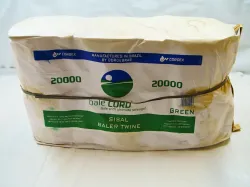

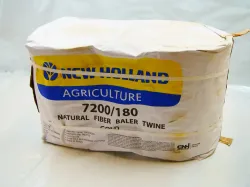

Sisal Twine

Sisal twine is made from natural fibers extracted from the agave plant. These fibers are processed and woven into twine, making sisal a biodegradable option. Sisal twine is typically labeled by length rather than knot strength due to natural variability in the fibers.

While sisal does have a knot strength rating, usually around 130 to 170 pounds, it is less consistent than synthetic options. Sisal is best suited for lighter bales and applications where biodegradability is a priority.

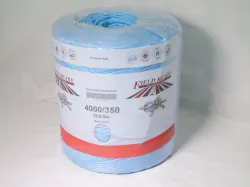

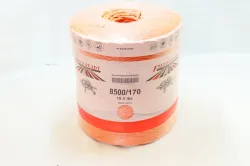

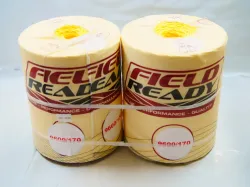

Poly Twine

Poly twine is a plastic-based product and is by far the most common twine used today. It is sold in both treated and untreated versions. Treated poly twine includes additives that help resist mold and rodent damage, making it ideal for most square baling applications.

Untreated poly twine is typically used in round balers where bales will be wrapped in plastic. The absence of chemical treatments prevents long-term damage to the plastic wrap.

Understanding Knot Strength and Length

Poly twine is sold using two key specifications: length and knot strength. Knot strength refers to how many pounds of force a knotted section of twine can withstand before breaking. Ratings can range from around 130 pounds for small square balers up to 650 pounds for large, heavy bales.

Higher knot strength usually means thicker twine, which results in fewer feet per ball. While thicker twine requires more frequent changes, it significantly reduces the risk of broken bales and lost time in the field.

Country of Origin and Why It Matters

There are only a handful of mills worldwide that manufacture baler twine, even though it is sold under many brand names. One of the biggest differences between twines is how they are rated.

Domestically produced twines, such as Bridon, are rated using minimum specifications. If a bale is labeled as 440 knot strength and 4,000 feet long, every section of twine meets or exceeds that rating. Imported twines are typically rated using averages, meaning variations in strength or length can occur within the same bale.

While imported twines are often less expensive, domestic products offer greater consistency, which many operators find worth the additional cost.

Twine Color Does Not Affect Performance

Baler twine is available in many colors, but color does not indicate strength, quality, or performance. Instead, color is often used for organization. Some operators run different colors for different cuttings, customers, or production runs to simplify identification later.

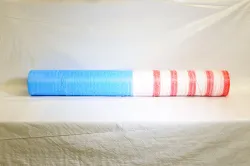

Net Wrap: Why Many Operators Are Switching

Many round bale operators have moved away from twine in favor of net wrap. Net wrap provides better bale coverage, improved shape, and faster wrapping times. While there are many brands available, consistency is the key differentiator.

TamaNet is widely recognized as the premium manufacturer in the net wrap market. Many OEM-labeled net wraps are produced by TamaNet, even if they carry a different brand name. Lower-cost net wraps may require additional wraps per bale or exhibit thin spots, reducing efficiency and protection.

Choosing the Right Net Wrap Width

Net wraps are sold in different widths depending on baler design. Balers with over-the-edge net systems typically require a wider net than the bale itself. For example, a 48-inch bale commonly uses a 51-inch net wrap to ensure full edge coverage.

Older or narrower balers without over-the-edge capability generally use net wrap sized to the bale chamber width.

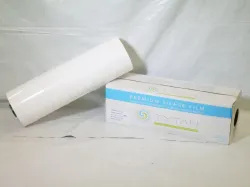

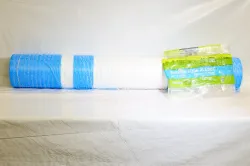

Silage Wrap and Plastic Film Considerations

Silage wrap performance can vary based on humidity, equipment setup, and handling practices. Unlike twine, plastic wraps require careful tuning of the baler or wrapper to work properly.

Once a wrap brand is proven to work well in a specific operation, it is generally recommended to stick with it. Frequently switching brands often leads to additional setup time and inconsistent results.

Frequently Asked Questions

What is the difference between sisal and poly baler twine?

Sisal twine is made from natural agave fibers and is biodegradable, while poly twine is a synthetic plastic product that offers greater consistency, strength, and resistance to moisture and pests.

What does knot strength mean on baler twine?

Knot strength refers to how many pounds of force a knotted section of twine can handle before breaking. Higher knot strength is needed for larger, heavier, or wetter bales.

Why does country of origin matter for baler twine?

Some manufacturers rate twine using minimum specifications, ensuring consistent strength and length throughout the bale. Others use average ratings, which can lead to variation and inconsistency.

Does twine color indicate quality or strength?

No. Twine color is purely for identification and organization and has no impact on strength or performance.

Why choose premium net wrap over lower-cost options?

Premium net wraps offer better consistency, fewer thin spots, and reliable coverage, reducing the need for extra wraps and improving overall bale protection.